CDMO/CMO

1Tech transfer

Experienced RD team performs R&D bridging and gap analysis with clients at the R&D stage.

2Chemical, Manufacturing and Control

Process Development team develops GMP-compliant production process to assist clients in CMC preparation.

3Investigational New Drug

Process Development team designs process scale-up while RD and QC team develop customized assays. We offer integrated services to assist clients at the IND filing stage.

4Batch Production

We provide CMO services to meet clients’ needs for clinical trials and product sales.

CDMO/CMO

1Tech transfer

Experienced RD team performs R&D bridging and gap analysis with clients at the R&D stage.

2Chemical, Manufacturing and Control

Process Development team develops GMP-compliant production process to assist clients in CMC preparation.

3Investigational New Drug

Process Development team designs process scale-up while RD and QC team develop customized assays. We offer integrated services to assist clients at the IND filing stage.

4Batch Production

We provide CMO services to meet clients’ needs for clinical trials and product sales.

Safety and functional assays for cell therapy products

Customized assay development1

Integrated RD and QC team to develop customized assays based on polymerase chain reaction (PCR), Enzyme-linked immunosorbent assay (ELISA), or flow cytometry technology.

Standard assays2

Other than customized assays, we also perform standard assays routinely performed in cell therapy industry

Safety and functional assays for cell therapy products

1Customized assay development

Integrated RD and QC team to develop customized assays based on polymerase chain reaction (PCR), Enzyme-linked immunosorbent assay (ELISA), or flow cytometry technology.

2Standard assays

Other than customized assays, we also perform standard assays routinely performed in cell therapy industry

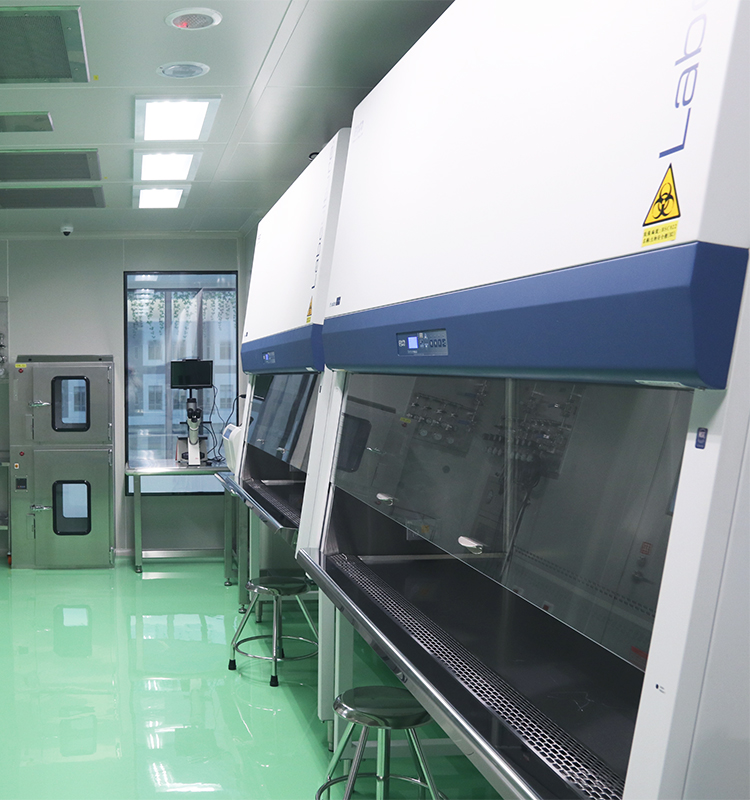

Cell Processing Center (CPC)

PIC/S GMP for ATMP

TaiwanBio’s Cell Processing Center (CPC) is designed to meet the latest EMA ATMP GMP, PIC/S GMP, and GTP requirements.

Simultaneous production of genetically engineered and non-genetically engineered cells

Out of the 12 cell processing units (CPUs) in our CPC, 3 are dedicated to mass genetically engineered cell production and equipped with full total exhaust biosafety cabinets in a negative pressure environment. Through our smart design to mitigate cross-contamination risk, we are able to manufacture genetically engineered and non-genetically engineered cells in different CPUs at the same time.

Pilot CPUs in R&D Center

To accelerate tech transfer for our clients, our R&D center was built with pilot CPUs. By using the same equipment as that used in the CPUs in our CPC, process developed in pilot CPUs can be seamlessly transferred to our CPC for PIC/S GMP production.

PIC/S GMP for ATMP

TaiwanBio’s Cell Processing Center (CPC) is designed to meet the latest EMA ATMP GMP, PIC/S GMP, and GTP requirements.

Simultaneous production of genetically engineered and non-genetically engineered cells

Out of the 12 cell processing units (CPUs) in our CPC, 3 are dedicated to mass genetically engineered cell production and equipped with full total exhaust biosafety cabinets in a negative pressure environment. Through our smart design to mitigate cross-contamination risk, we are able to manufacture genetically engineered and non-genetically engineered cells in different CPUs at the same time.

Pilot CPUs in R&D Center

To accelerate tech transfer for our clients, our R&D center was built with pilot CPUs. By using the same equipment as that used in the CPUs in our CPC, process developed in pilot CPUs can be seamlessly transferred to our CPC for PIC/S GMP production.

A “total solution” business model

TaiwanBio provides one-stop CDMO services to streamline our clients’ cell therapy development. In addition to the 12 CPUs, our CPC is also equipped with in-house QC facilities. In addition, our R&D center is built with pilot CPUs to allow seamless transfer of developed process to PIC/s GMP production in our CPC.

A “total solution” business model

TaiwanBio provides one-stop CDMO services to streamline our clients’ cell therapy development. In addition to the 12 CPUs, our CPC is also equipped with in-house QC facilities. In addition, our R&D center is built with pilot CPUs to allow seamless transfer of developed process to PIC/s GMP production in our CPC.